IISER Pune researchers Dr. R. Vaidhyanathan and team have developed a new material that can selectively capture and remove carbon dioxide (CO2) from a gaseous mixture with hydrogen (H2). This can facilitate a more efficient purification of hydrogen, a known non-polluting fuel. The new material could be eventually developed for commercial use in an alternative energy-efficient method for producing usable energy from fossil fuels.

Dr. Vaidhyanathan, a materials chemist, works towards developing porous solids belonging to the class 'Metal Organic Frameworks’ (MOFs). “MOFs are porous, crystalline structures made by linking metal ions with organic ligands”, he explains. The pores can accommodate gases and small molecules. Moreover, their organic backbone can be designed to bind preferentially to some molecules, making MOFs ideal molecular sieves for separation of gaseous mixtures.

An important application for such MOFs is in two important energy production technologies, ‘pre-combustion capture’ and ‘steam methane reformation’. Both of these involve two fundamental processes, ‘gasification’ and ‘water-gas shift reaction’ that produce a gaseous mixture of CO2 and H2. Pure H2 is obtained from this mixture by a method called Pressure Swing Adsorption (PSA). Porous materials like zeolites are currently used as sorbents in PSA, with CO2 adsorbing onto them under high pressure and getting released at lower pressure. But this is an energy-demanding process, making large scale coal gasification power plants commercially unviable.

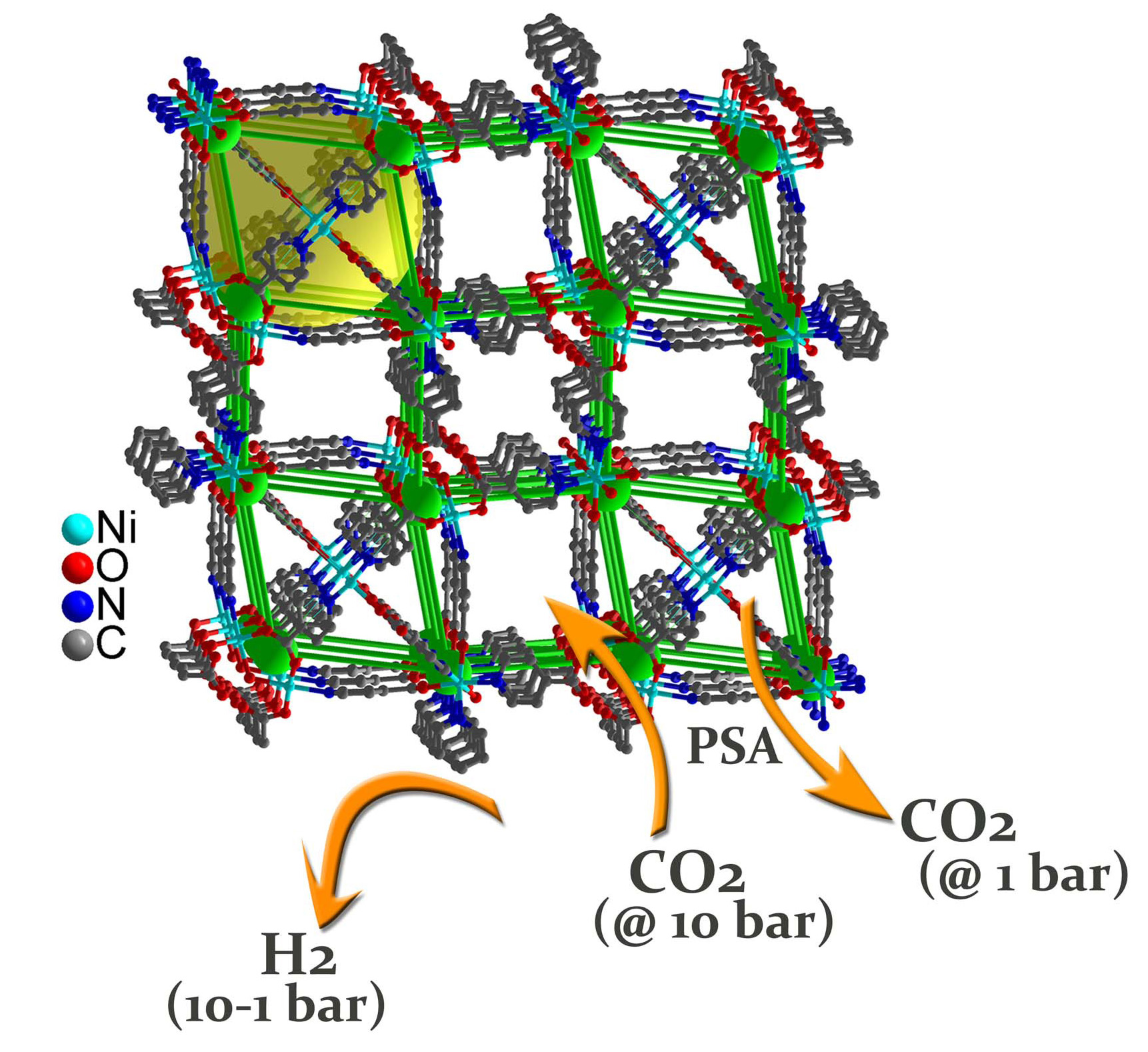

[caption id="attachment_599" align="alignleft" width="400"] (Left) The new ultra-microporous nickel-isonicotinate MOF; (Right) Real-time CO2 separation from CO2:H2 precombustion gas mix (Ref: Nandi et al (2015) Science Advances)[/caption]

With inputs of computational simulations and analysis from Dr. Tom Woo’s group at University of Ottawa, Dr. Vaidhyanathan and PhD student Shyamapada Nandi have developed an ultra-microporous nickel-isonicotinate MOF that can selectively and efficiently capture CO2 using a 10 to 1 bar pressure swing. Efficiency of sorbents is generally defined by its ‘working capacity’ - measured as the amount of CO2 that can be captured and recovered for each pressure swing cycle.

(Left) The new ultra-microporous nickel-isonicotinate MOF; (Right) Real-time CO2 separation from CO2:H2 precombustion gas mix (Ref: Nandi et al (2015) Science Advances)[/caption]

With inputs of computational simulations and analysis from Dr. Tom Woo’s group at University of Ottawa, Dr. Vaidhyanathan and PhD student Shyamapada Nandi have developed an ultra-microporous nickel-isonicotinate MOF that can selectively and efficiently capture CO2 using a 10 to 1 bar pressure swing. Efficiency of sorbents is generally defined by its ‘working capacity’ - measured as the amount of CO2 that can be captured and recovered for each pressure swing cycle.

The new MOF exhibits an exceptionally high working capacity, two orders of magnitude higher than the commercial zeolite-13x, making it suitable for industrial use. Made from a single, small ligand, it is rigid and chemically stable with a long shelf-life. It can withstand humid conditions of the gasification process. Another advantage of this MOF is the simple, one-pot synthesis process of production and easy scalability.

[caption id="attachment_600" align="alignright" width="450"] PhD student Shyamapada Nandi and R. Vaidhyanathan in their lab at IISER Pune[/caption]

PhD student Shyamapada Nandi and R. Vaidhyanathan in their lab at IISER Pune[/caption]

Though the potential is high, Dr. Vaidhyanathan cautions that challenges in the use of MOFs for large scale applications are far from over. Prolonged life under operating conditions that involve acidic or basic gas streams and high temperatures is a tough expectation to meet. But he states, “Our work along with other recent findings on rigid ultra-microporous large surface area MOFs could provide scalable sorbents with the right stability and working capacity”.

This work was published in the latest issue of Science Advances as a paper titled “A single ligand ultra-microporous MOF for pre-combustion CO2 capture and hydrogen purification”, authored by Shyamapada Nandi, Phil De Luna, Thomas Daff, Jens Rother, Ming Liu, William Buchanan, Ayman I. Hawari, Tom K. Woo and Ramanathan Vaidhyanathan.